Offshore Wind

Site and Process safety is crucial in offshore wind energy because it ensures the protection of people, the environment, and assets during the design, operation, and maintenance of offshore wind farms. Here's why it's particularly important.

Harsh and Remote Environment

Risk of Hazardous Materials

Heavy Equipment and High-Voltage Systems

Personnel Safety

Environmental Protection

Regulatory Compliance

Cost Efficiency

Oil & Gas

Site and Process safety is critical in the oil and gas industry because it directly impacts the safety of workers, the environment, and the integrity of the assets involved. The oil and gas sector deals with high-risk processes, hazardous materials, and potentially catastrophic events, which makes process safety indispensable. Here are several reasons why it's so important.

Protection of People

Environmental Protection

Prevention of Catastrophic Events

Regulatory Compliance

Asset Protection and Operational Integrity

Cost Reduction and Efficiency

Reputation and Trust

Crisis Management and Preparedness

Long-Term Sustainability

Functional modules

The following is a list of the software modules that exist in eLogbook to support both Site & Process safety.

Handovers & Events

Efficient handovers, be they shift or trip based, are critical to operational visibility of all events affecting an asset.

Operational assurance tasks

The ability to capture action and task management data allows for the detailed recording of an action and corresponding tasks with scheduling and performing competency.

Communications tracker

The importance of communicating with all staff and contractors as to changes in process, policy or standards can be audited and measured in terms of understanding and compliance.

Operational risk assessment

The adoption of rigorous and streamlined ORA practises is a key focus for process operators especially so at the present time with increased pressure on efficiency of operational cost and safety.

Management of Change

The tracking and management of the approval of asset changes through single point reference and collaboration with verification and asset integrity at the fore of decision making.

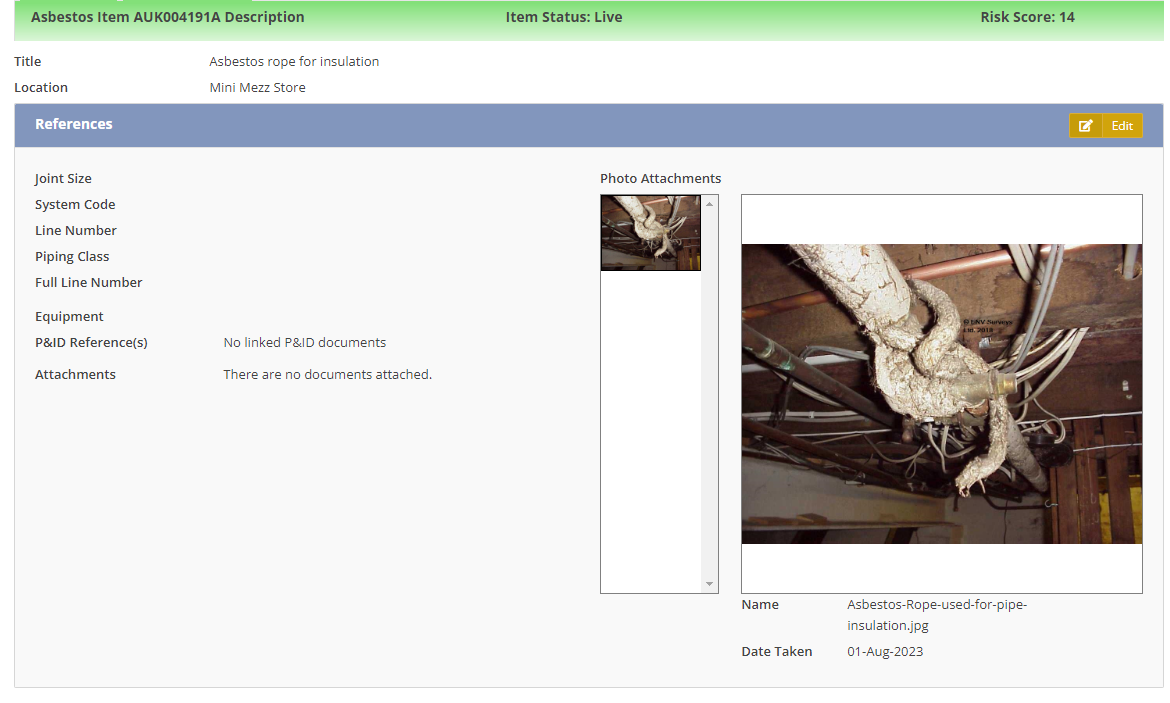

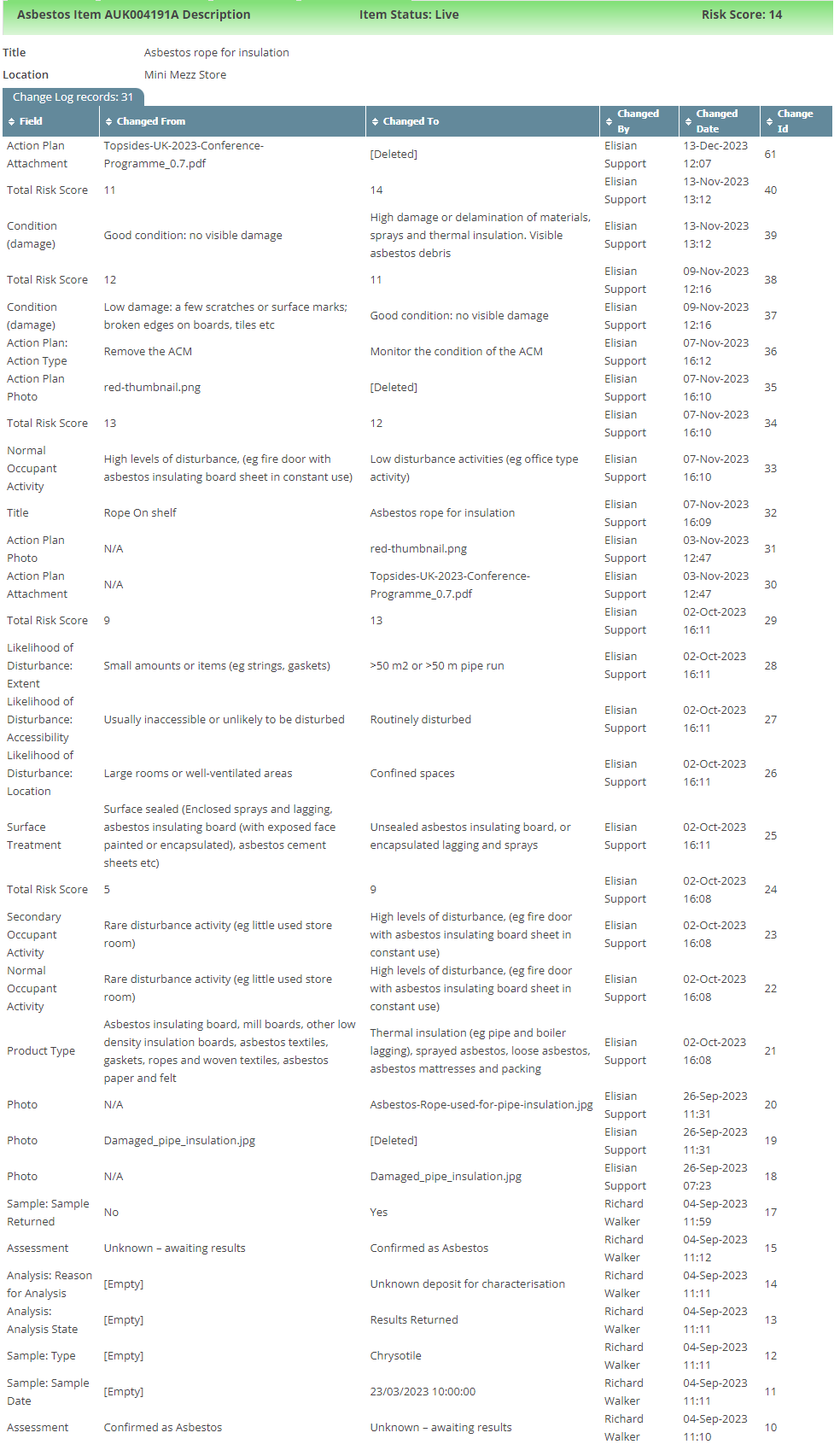

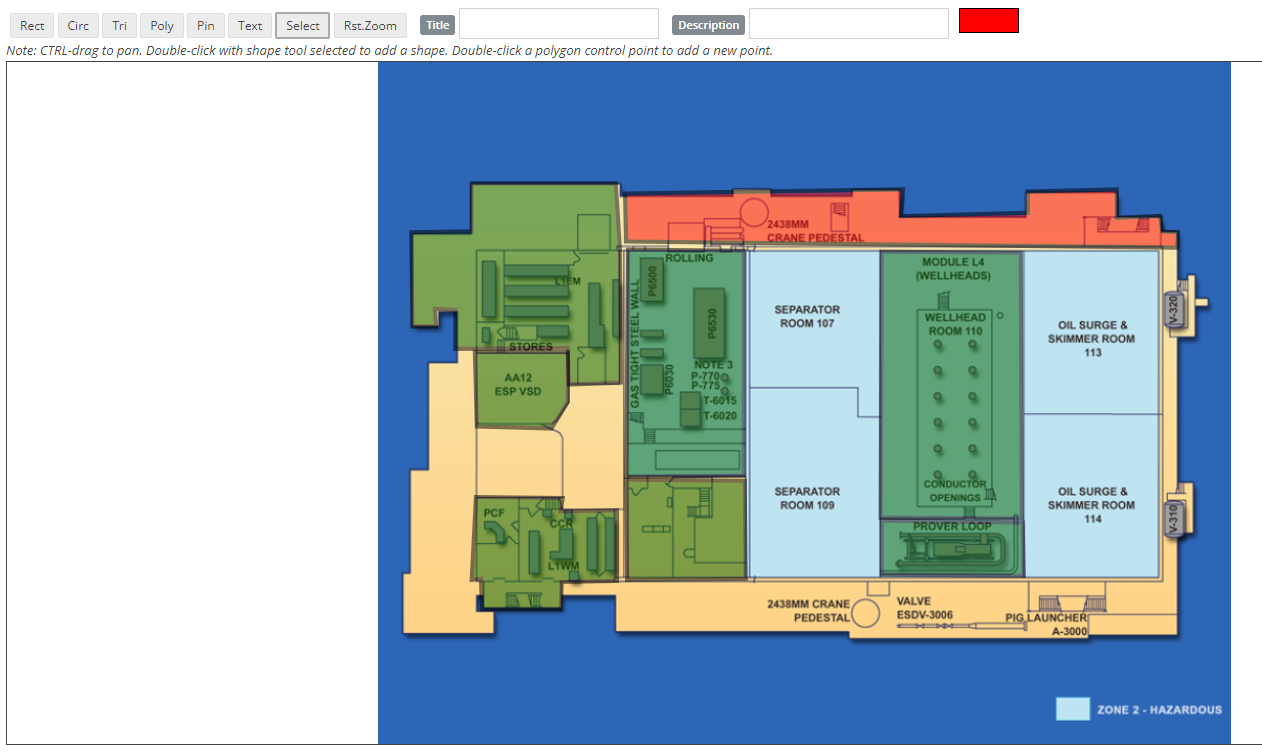

Hazard mapping

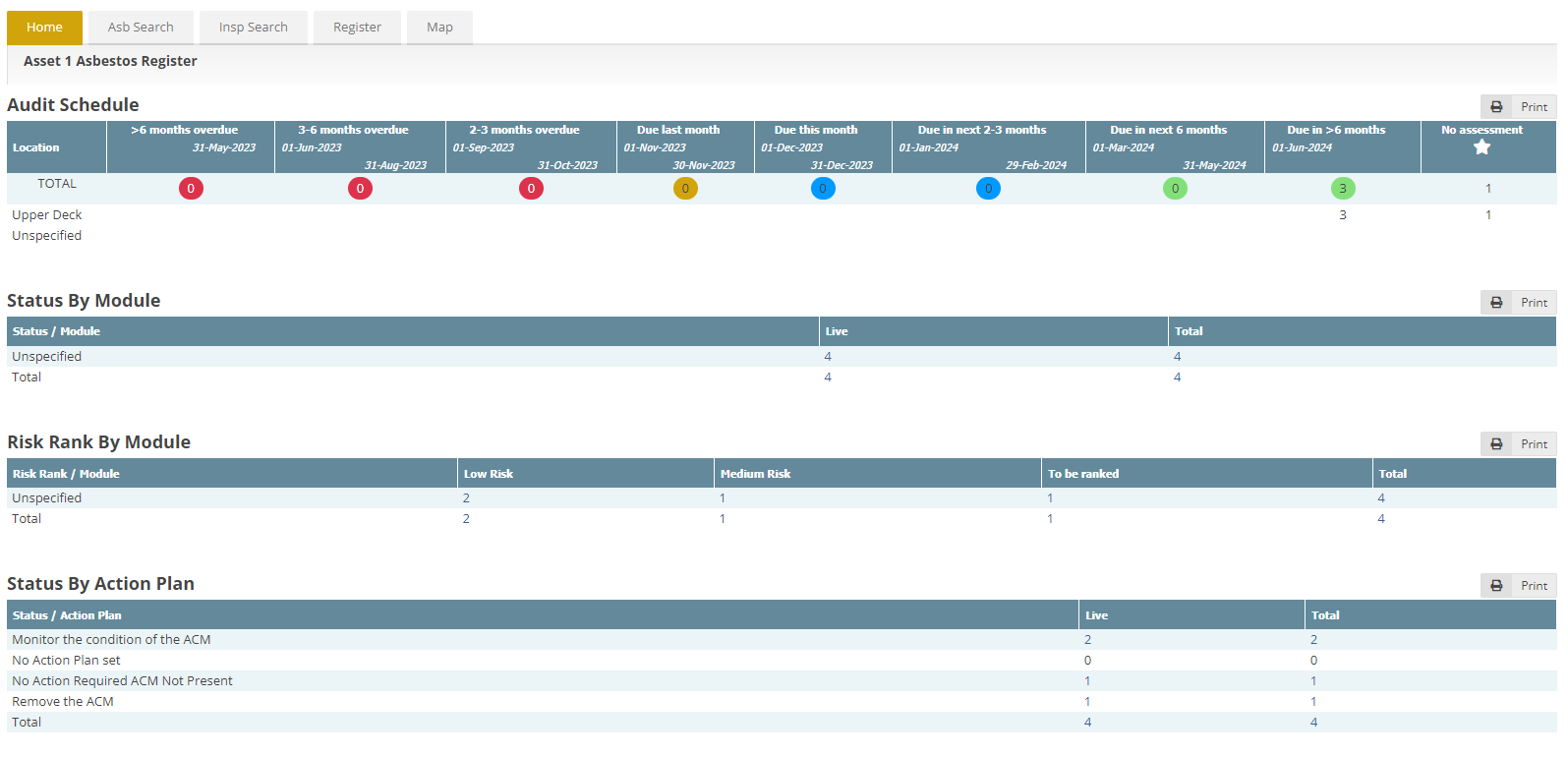

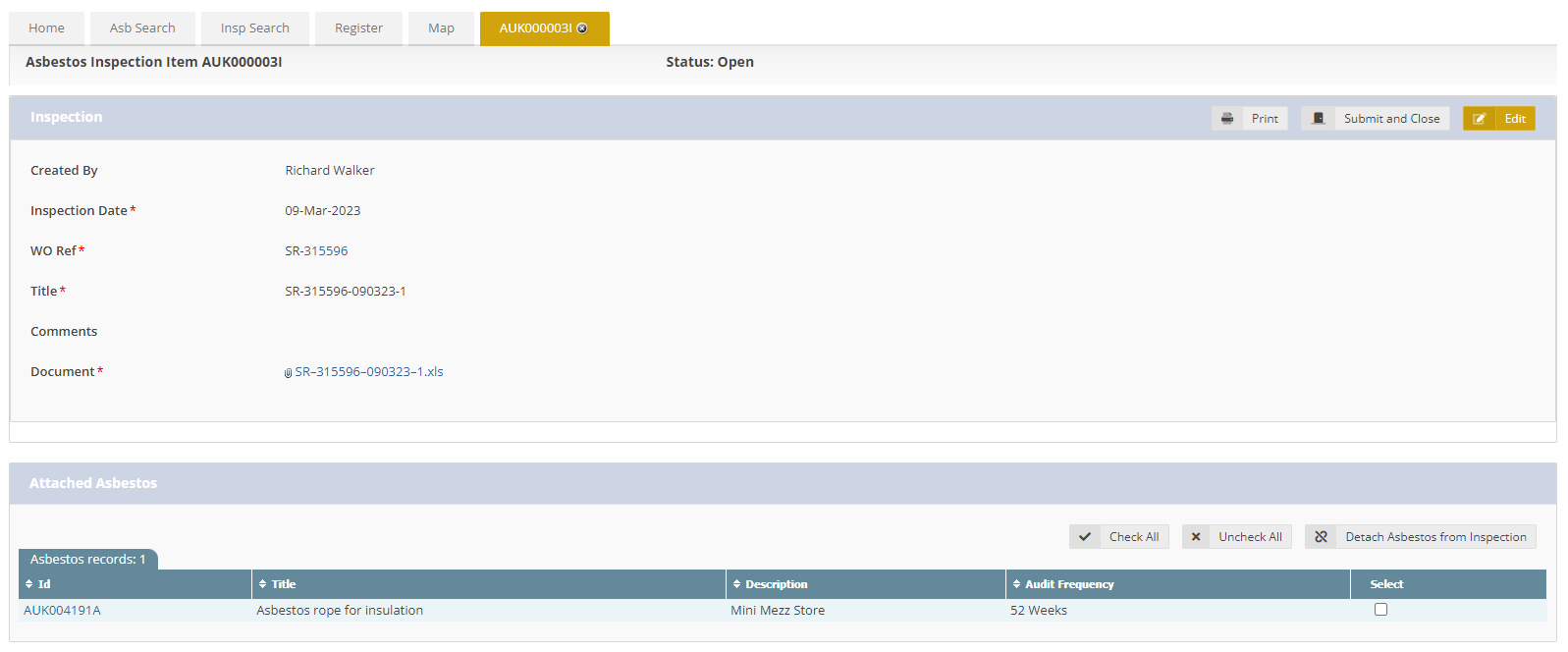

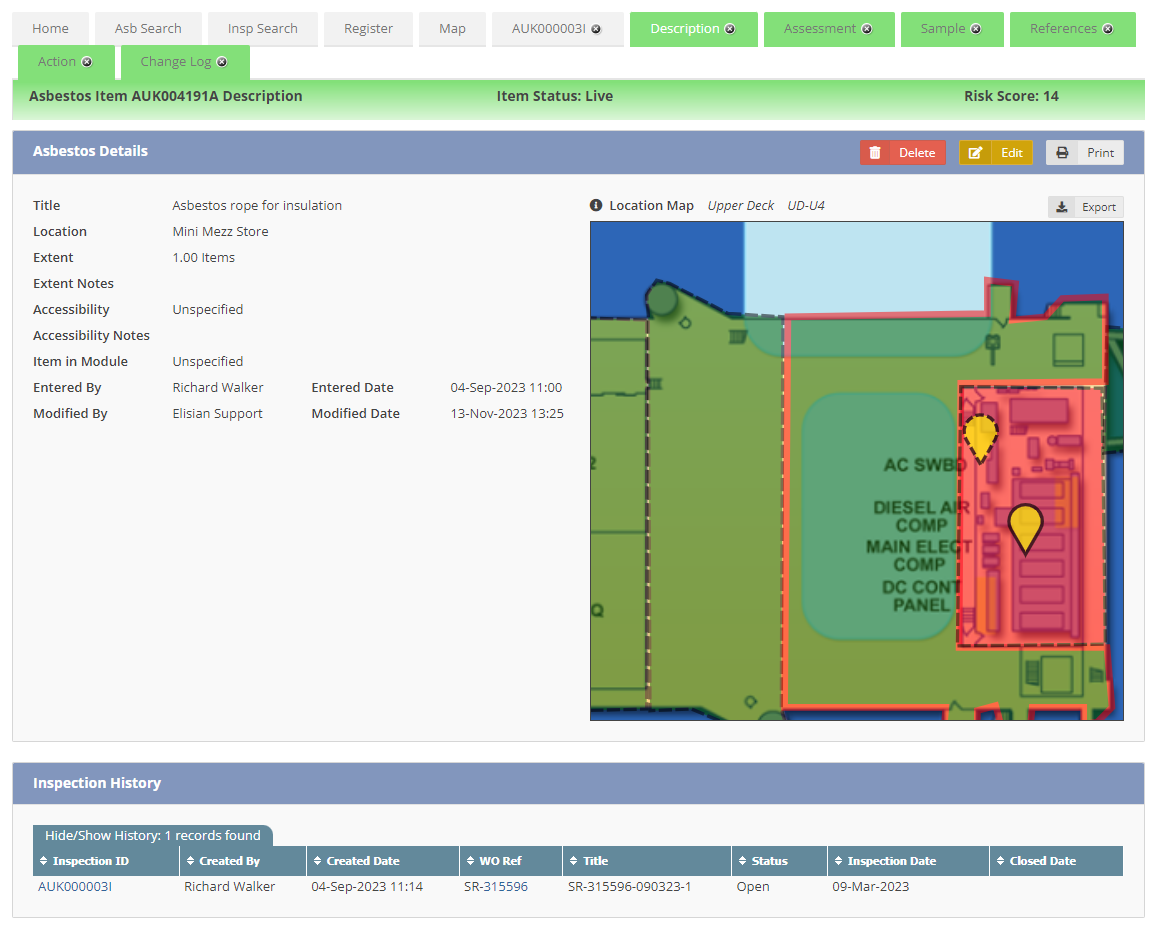

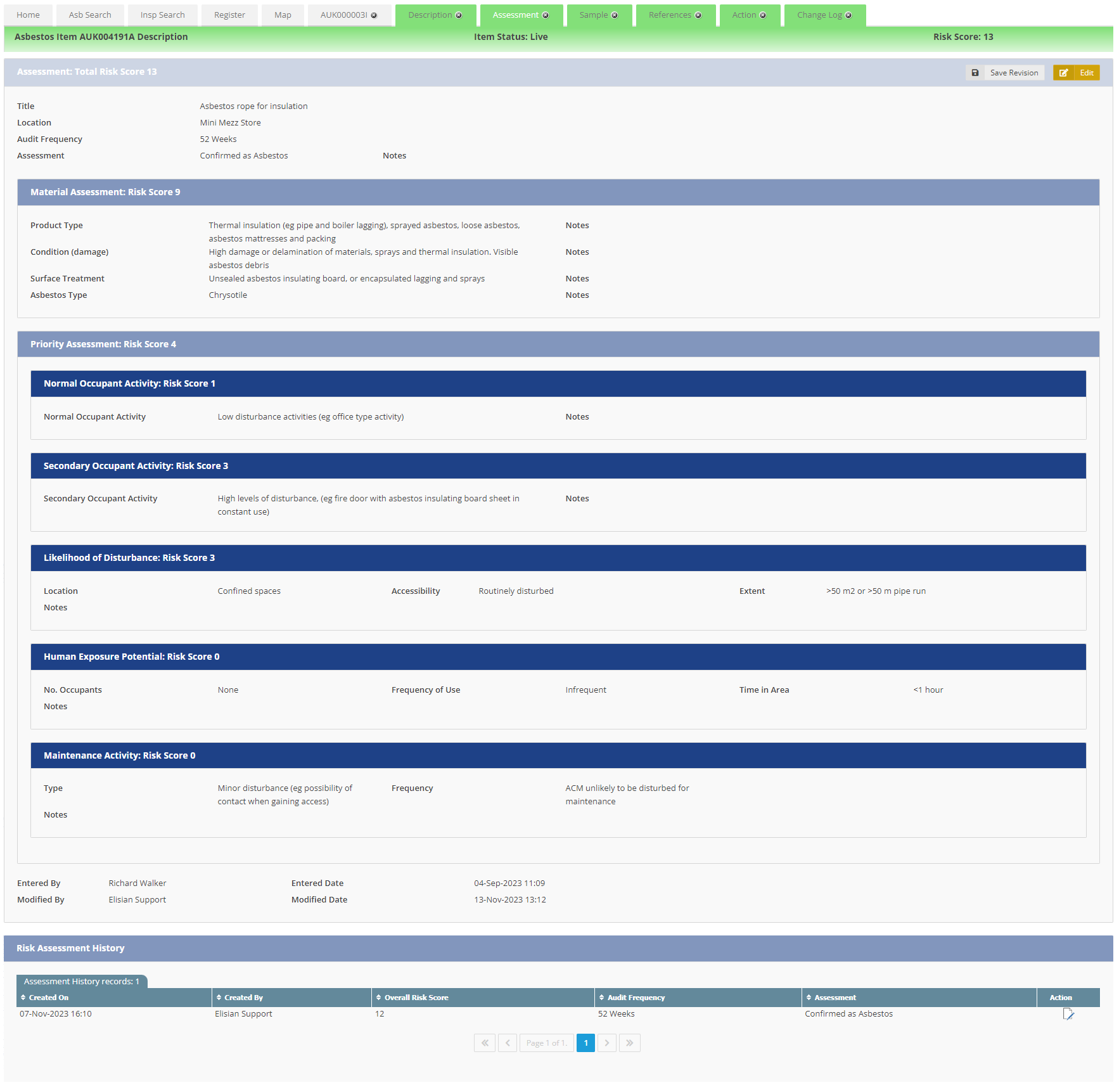

Th ability to collect, analyse and visual map hazards around an asset including asbestos, water hygiene and fire is common to most assets. The ability to capture other hazards such as noise, lead, benzene, mercury, damp/mould and RAAC support safety operations around an asset.

Root causes analysis

With globally ageing assets which are being asked to reliabily work harder and longer, it is critical that failures are analysed and understood to prolong the life of an asset or equipment.

Process safety overrides

Where appropriate processes may be overridden in a manner that is compliant with accepted procedures and that do not exceed safety parameters for either equipment or asset integrity.

Locked valve register

When working in environments that process liquids or gases, it is important to record all movement of valves from locked open to locked closed and have these movements audited and approved to ensure asset safety and integrity.

Permit to Work

The issuing and management of a permit ensures that an area of an asset where people may be working is safe and secure as well as being controlled by all interested parties as to when the permit has been completed and the area is safe to come back into operational use.

Features

- All

- Details

- Mapping

- Risk

- Scheduling